Enterprising to the Core

WBE Tec-Crete Transit-Mix holds its own in the Big Apple

A work ethic cultivated by a range of duties—filling sand bags to office work—for her father’s New York City ready-mix business, F&M Transit Mix in Jamaica, Queens, more than paid off for Linda Gisonda in adult life. Indeed, she is the sole proprietor of a two-plant operation filling mixer trucks with high performance concrete that exceeds engineer targets on jobs no less than New York City’s tallest office building, the 1,401-ft. One Vanderbilt.

Tec-Crete Transit-Mix Corp., the business Linda founded in 1998, is the Big Apple’s premier union WBE ready mixed concrete producer. It holds Women Business Enterprise certifications for Empire State Development (NYS) and the Port Authority of New York and New Jersey. As the head of a true family business, Linda recalls telling her husband Michael, who was among her employees, as well as their son Michael Giulio Gisonda and daughter Mariangela Gisonda Betancourt, of her plans to start her own ready-mix operation after her father shut F&M Transit Mix down.

Although she launched Tec-Crete with an eye to public work in the Queens and Brooklyn boroughs, an early opportunity surfaced across the East River in Manhattan: Completion of a ready mixed supply contract at City Hall, where then-Mayor Rudy Giuliani made no secret of his openness to enlisting producers outside the old concrete guard. The City Hall project participation helped Tec-Crete get off the ground running and garner concrete orders for municipal or state projects, along with La Guardia Airport and JFK International Airport work under the Port Authority.

“There was limited WBE program oversight when we started out,” Linda notes. “That changed with high profile state and federal cases where contractors were fined or jailed for false WBE claims. Many contractors on public work now have compliance staff to confirm or verify subcontractor or supplier business ownership. My WBE status has faced challenges for years. Detectives and law enforcement officials frequently monitored me for evidence to counter my valid claim.” Customers are assured of WBE procurement compliance, she adds, thanks to Tec-Crete’s dogged adherence to Port Authority and Empire State Development audit requirements and recertification cycles.

Michael and Linda Gisonda with children Michael G. Gisonda and Mariangela Gisonda Betancourt.

NEW LEAGUE, NEW ERA

Nearly 10 years out from its founding, Tec-Crete Transit-Mix earned a contract with Tutor Perini Corp. as ready mixed supplier for the New York Metropolitan Transportation Authority East Side Access Tunnel. Like the City Hall job, the initial 20,000-yd. MTA contract in 2007 served as an inflection point, after which Tec-Crete was better recognized for higher volume project capabilities.

The MTA contract and other major city, state or Port Authority jobs positioned Tec-Crete to gain a larger share of New York City ready mixed concrete volume throughout the company’s second decade—ahead of a major shift in producer ranks. Just as Tec-Crete was gaining momentum, larger companies decided to enter the New York City market and buy out local independent producers serving its five boroughs. Throughout the dealmaking, strong Metro New York-New Jersey demand for concrete has reflected Port Authority capital project outlays—budgeted at just under $30 billion for 2017-2026—coupled with a historically robust window of high-rise residential or commercial building construction.

Leading the flourish were five luxury Manhattan residential towers in the 1,000- to 1,500-ft. height class—dubbed “supertalls” by Wall Street Journal reporter Katherine Clark in Billionaire’s Row (2023). One Vanderbilt, a sixth supertall, rose in 2017-2019. The commercial office building’s nearly 80,000-yd. contract represented a third inflection point for Tec-Crete, which supplied the job from both the Jamaica plant and a second Queens plant in Maspeth. The latter operation was recently replaced with construction of a batch plant in the borough’s Long Island City section. The dual-lane, wet-dry facility lies on a 2.5-acre parcel parallel to the Interstate 495/Long Island Expressway and about two miles east of One Vanderbilt.

“This new plant provides two access points (Queens-Midtown Tunnel and 59th Street Bridge) to Manhattan for high-rise building work, and still good routing for infrastructure deliveries,” says Michael G. Gisonda, who oversees sales and quality control for Tec- Crete. “Although much New York City ready mixed concrete capacity is transit mixed, we decided to go with a dual wet-dry alley plant similar to ones Vince Hagan Company builds in other major markets. We anticipate central mixed production capability adding speed and efficiency to a variety of work with predictable delivery times.”

A few months into operation, Tec-Crete’s Long Island City plant assisted Empire Transit Mix Inc. with a 5,600-yd. continuous mat pour for 589 Brooklyn St., along with fellow independent Casa Ready Mix. The job set a new single-placement watermark for a Big Apple building project. Compared to foundation pours in other major markets, where volumes can reach into the five-digit yardage range, the 589 Brooklyn delivery seems modest but underscores land scarcity and development challenges unique to New York City. Those challenges especially apply in Manhattan where, post World Trade Center site redevelopment, the idea of a single foundation spanning a full square block—or a long line of mixers dramatically staged for rapid unloading—is highly implausible.

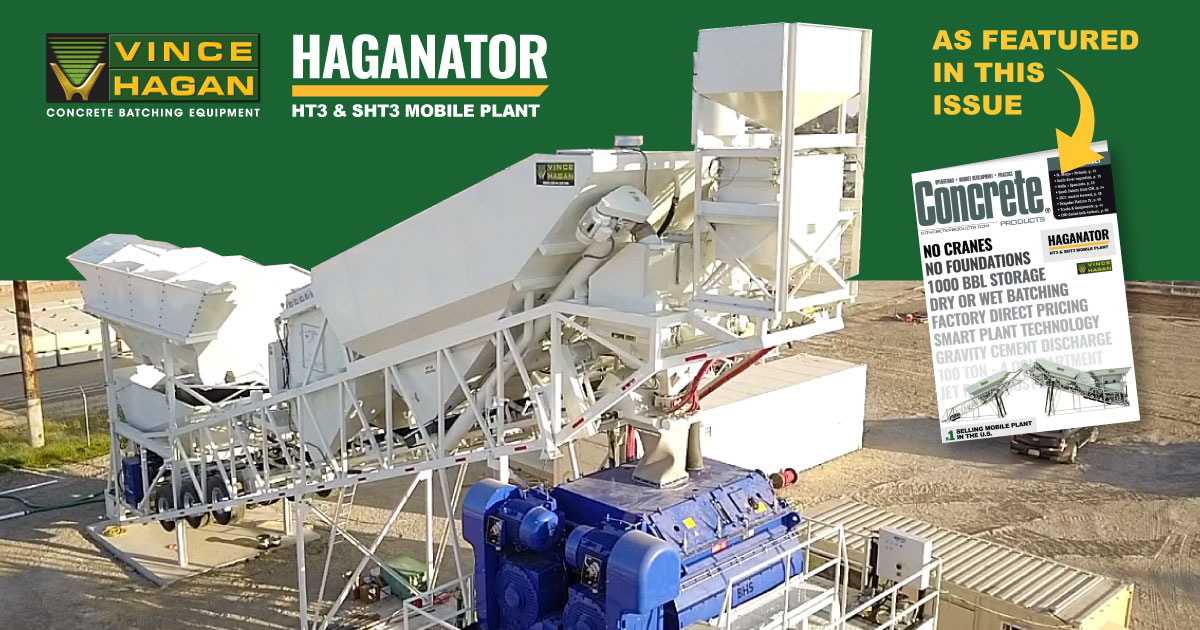

Vince Hagan Co. engineered and fabricated a standard dual lane LPM Model for the Tec-Crete Transit-Mix Long Island City plant, configured as wet-dry or both dry. The 12-yd. tilting drum is equipped with PLC sensors, which support automation by alerting the batch operator with what action to take, but not prescribing how. The PLC capability enables Vince Hagan engineers to remotely write new instructions or functions into the logic without the need for external wiring or switches. The Long Island City equipment arrived from Texas in 18 truckloads, 12 of them permitted and all subject to the tight navigation typical of the New York City street grid.

The three 1,200-bbl silos are split: two 50/50, the third 70/30. The south sides of the yard and central shop building harbor a total of six aggregate stockpiles.

The One Vanderbilt supply contract moved Tec-Crete Transit-Mix into the next tier of ready mixed producers—those whose quality control and delivery track records earn contractor and engineer confidence for elite work. A design of New York-based Kohn Pederson Fox, the 1,401-ft. tower rises along the west side of the Grand Central Terminal.

Second Generation, First-Rate Determination

The Long Island City plant became the largest financial commitment in the 25-year history of Tec-Crete Transit-Mix Corp. and the producer’s first project with Dallas-based Vince Hagan Co. After embracing lessons from fathers who had carved out post-war building boom concrete niches, the Tec-Crete and Vince Hagan Co. chiefs have both excelled in male-dominated construction circles.

In a market where customer service and contractor or owner relationships eclipse branding, Linda Gisonda (right) founded Tec-Crete, pursuing a career path other than joining F&M Transit Mix. Immigrating from Italy to New York, her father Giulio Marini started his ready-mix family business in the early 1960s with a B-model mixer truck named Angela, exiting about 30 years later with a fleet of 30-plus.

In concrete plant equipment, where brand equity carries a premium, Carol Hagan (left) has steered the Vince Hagan Co. for more than 25 years. Her father opened his eponymous shop in 1956, staking claim with a portable batch plant ultimately named The Haganator. The mobile equipment proposition was astutely timed with a market fueled by that year’s Federal-Aid Highway Act.

Buy Clean Ready

Tec-Crete Transit-Mix headquarters has moved from Jamaica to an existing two-story building at the Long Island City property. The new facility has ample dispatch office space for a fleet approaching 50 mixer trucks, plus meeting areas to accommodate customers, agencies, design or engineering professionals, and other visitors.

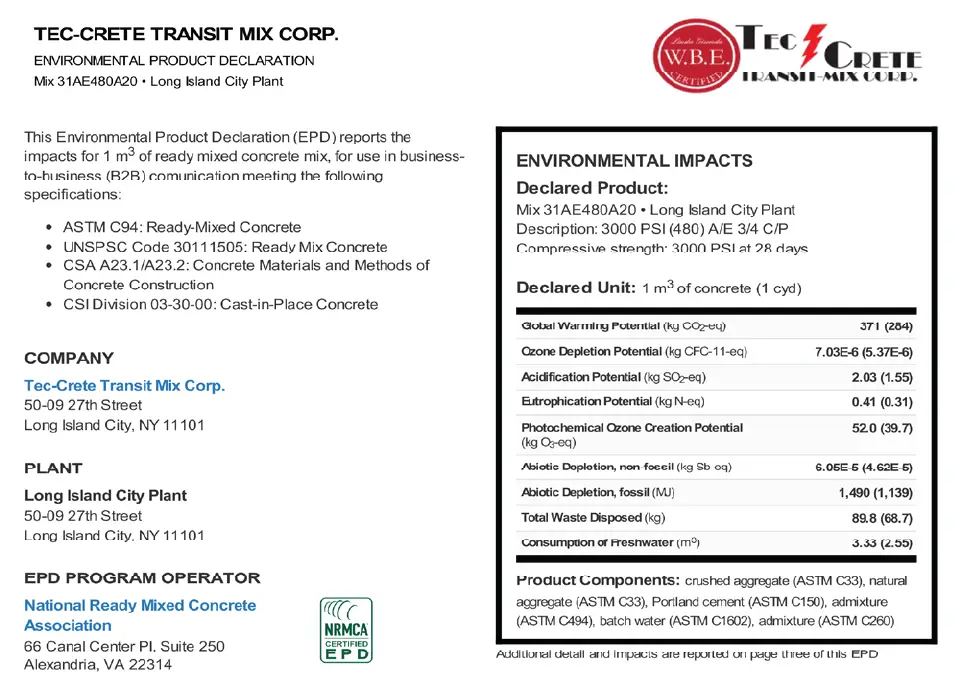

Contractors, prospects and owners’ representatives who are abiding the New York State Department of Transportation Buy Clean measure or Low Embodied Carbon Concrete Leadership Act, for example, will find in Tec-Crete a producer that has a) migrated from ASTM C150 Type I/II portland cement to C1157 Type IL portland limestone cement; b) equipped its two plants with supplementary cementitious materials storage for a range of portland cement substitution options; and, c) adopted the Climate Earth platform generating environmental product declarations on demand for projects with EPD submittal requirements or, in the case of LEED certification, incentives.

“Tec-Crete has earned credibility by servicing high-strength concrete orders and the largest of projects with a capable fleet and strategically located plants,” Linda Gisonda affirms. “We are prepared to meet the Buy Clean and Low Carbon movement with the same skills and dedication that brought us into the major infrastructure project and high-rise building markets.”

The Climate Earth EPD Generator equips Tec-Crete for rapid delivery of declarations covering Long Island City and Jamaica plants.

This article originally appeared in the January 2024 Edition of Concrete Products

Vince Hagan Co. continues to build a suite of technology features affording mobile or stationary concrete batch plant owners new, labor-saving remote operation, automated lubrication, diagnostic and preventative maintenance possibilities.

It is time for producers to optimize their plants as part of becoming least-hassle suppliers. Investing in plant automation will pave the way for a higher-quality product and more predictable logistics.

Vince Hagan’s portable Haganator Batch Plant paired with a BHS Twin Shaft Mixer and Hagan Mixer Structure used at the Dragados Flatiron Joint Venture facility was featured in the January 2021 edition of Concrete Products magazine.