Central Casting with Vince Hagan HT3 Haganator

With Covid-19 safety protocols firmly engrained for nearly a year, work continues on schedule at one of the highest volume precast, prestressed concrete yards in North America: the Dragados-Flatiron Joint Venture (DFJV) Pre-Cast Facility, Hanford, Calif. The 40-acre operation abuts expansive almond tree parcels along the midpoint of a 60-mile route defined in the design-build California High-Speed Rail Authority Construction Package 2-3 (CP 2-3).

Joint venture partners Dragados USA, Inc., New York, and Flatiron West Inc., Benicia, Calif., bring major infrastructure project experience, including fast track concrete work, in North America and international markets. Their current charge in the California Central Valley entails rail and right of way through Fresno, Tulare and Kings counties and the cities of Hanford, Corcoran and Allensworth. CP 2-3 represents a charter segment of the California High-Speed Rail, the masterplan for which contains inland and coastal routes from San Diego to San Francisco.

Helser Industries provided a twin, 600-ft. California Wide Flange form warranting deep bulkhead foundations equal to enormous stressing forces. The manufacturer also delivered self-stressing 300- and 400-ft. standalone CWF forms.

DFJV’s $1.5 billion-plus package encompasses at-grade, aerial, and possible below grade rail sections, built to tight tolerances enabling safe train passage at elevated speeds; relocation of existing BNSF tracks for approximately 5.5 miles; prospective crossing of existing BNSF railroad tracks; construction of waterway and wildlife structures; plus, roadway reconstructions or relocations and closures. In all, viaducts, underpasses or overpasses will accommodate 36 grade separations throughout the CP 2-3 expanse.

Dragados Flatiron Joint Venture production and engineering staff configured the 40-acre, Central Valley site around California Wide Flange (above, right and center) and tub girder (above, left) fabrication. The latter profiles suit a limited number of Construction Package 2-3 crossings with height or clearance limitations. Foundation work (top, foreground) for piers along an elevated California High Speed Rail stretch demonstrated heavy emphasis on prestressed square piles. Later in the construction schedule: Deck panels, cast in an auxiliary yard, are staged in between the Hanford right of way and DFJV Pre-Cast Facility. Hamilton Form Co. delivered formwork for the latter elements plus a 300-ft. bed for California Wide Flange girders. DRONE PHOTO: Dragados Flatiron Joint Venture

Concrete Schedule

Hanford Pre-Cast Facility crews have a four-year timeline, culminating in February 2022, to fabricate nearly 2,400 California Wide Flange (CWF) girders, 54 ft. to 151 ft. long and 42 in. to 120 in. deep; 90 tub girders, 44 ft. to 110 ft. long and 80 in. to 101 in. deep, weighing up to 500,000 lbs.; 12,000-plus deck panels, 3 ft. x 8 ft. to 8 ft. x 8 ft., for wide flange or tub girder structures; and, 100,000-plus linear feet of 14-in. square pile.

With a payroll peaking around 100, the yard has 14 casting points, led by 300-ft., 400-ft., and 600-ft. CWF beds and two tub girder forms. During higher production weeks, crews have cast 8,000 linear feet of pile, 5,000 linear feet of CWF girders, 100 linear feet of tub girders and nearly 8,000 square feet of deck panels. The plant carries Precast/Prestressed Concrete Institute and California Department of Transportation (Caltrans) certification, owing to different public or private land owner requirements for the 30-plus crossings within CP 2-3.

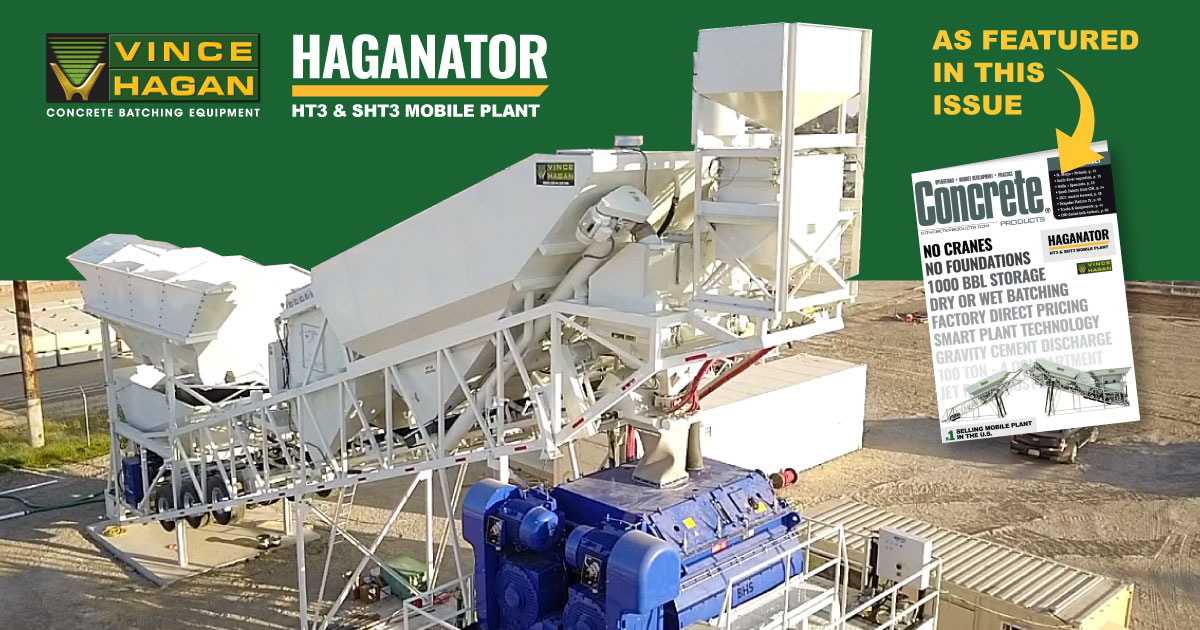

DFJV tailored a Vince Hagan HT Haganator portable plant and BHS DKX 6.0 twin shaft mixer for speedy output of high-fl ow concrete. A very narrow concrete schedule for girder, pile and deck panel fabrication is centered on sand and 3/8-in. crushed granite. Two grades of mixes with self-consolidating properties have suited most California Wide Flange or tub girder, girder deck panel and pile fabrication.

DFJV built a batch plant around production of self-consolidating type mixes, delivered via conventional mixer trucks, along with belts as needed to clear girder forms. The contractor combined a Vince Hagan HT Haganator with a BHS twin shaft mixer, the latter assuring short, but very robust cycles to yield high-flow concretes exhibiting 20-in. spreads with zero aggregate segregation. Anchoring the girder, panel and pile concrete schedule are mixes designed to reach 5,000 psi or 7,000 psi compressive strength in 24 hours. With Type III cement, 3/8-in. crushed granite, sand and Master Builders superplasticizers, the second mix has routinely attained strengths north of 9,000 psi. Daily output from the plant has ranged from 100 to 300 yd.

This article originally appered as the Cover Story in Concrete Products Magazine

Vince Hagan innovated, manufactured, and installed a Dual Alley LPM Stationary Concrete Batching Plant with a TM-12 Smart Tilt Mixer for Tec-Crete Transit Mix Corporation in the heart of New York City.

Ernst Concrete rounds out Atlanta market coverage with one of the Peach State’s largest ready mixed plants