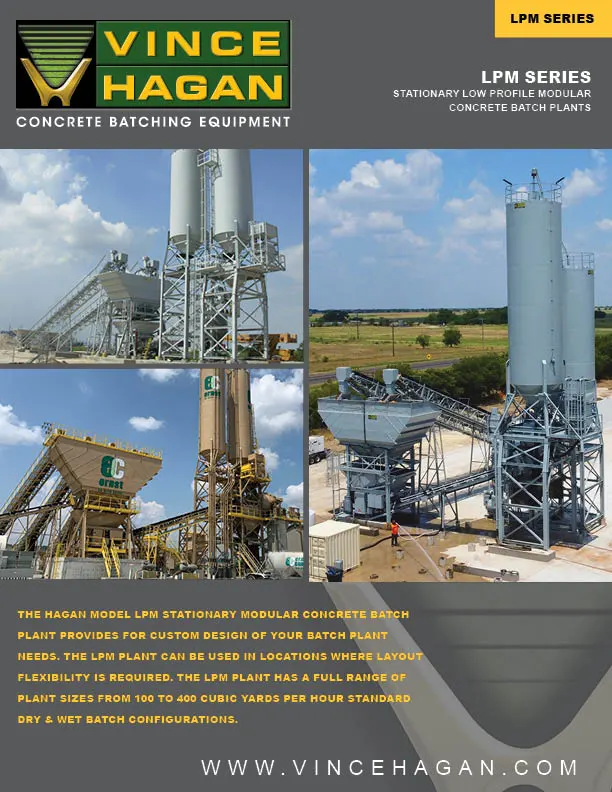

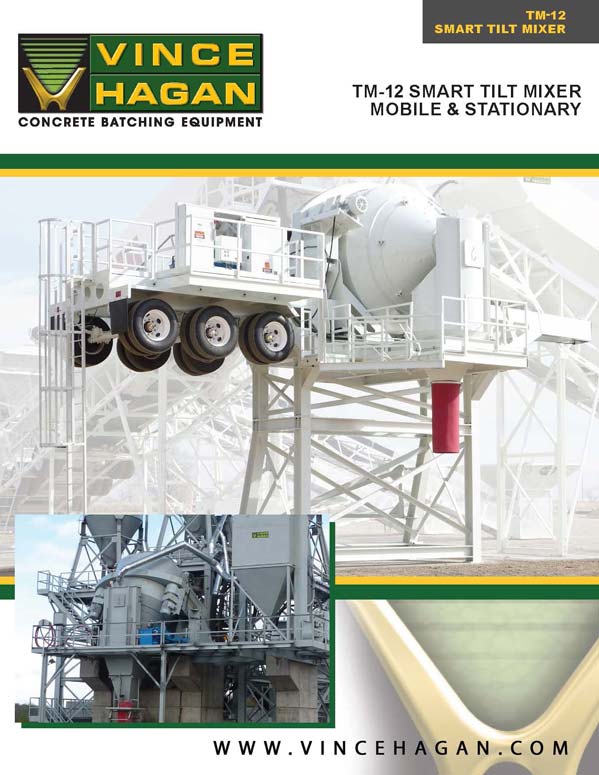

Add the exclusive upgrade Vince Hagan Holding Hopper to your high capacity HSM or LPM model stationary batch plant design and Hagan Stationary TM-12 Tilt Mixer to increase wet and dry batch capacity to up to 300 to 400 cubic yards per hour. The design allows the plant to simultaneously charge two ready mix trucks while the next batch is being weighed up. As soon as the holding hopper or tilt mixer is empty the batchers are ready to load into the empty lane and weigh up the next batch for faster production. This allows for three batches to be available for trucks waiting to be charged.

Specifications

- High-speed charging with 36″ or 48″ batch belt

- 36″ to 48″ batch belt design

- 60 to 400 ton aggregate storage capacity up to 8 compartments

- 300 to 1200 bbl. overhead cement storage capacity including optional two-compartment silo

- Auxiliary silos from 300 to 1200 bbl. cement storage capacity including optional two-compartment silo

- Auxiliary silos straddle the batch belt for compact foundation design

- Auxiliary silo has 7″ to 12″ screw feeders for fast and accurate feed of cements

- 12 cu. yd aggregate and cement batchers

- 2″ temper metered water feed system

Features

- One 12 cu. yd capacity hopper with separate storage for the aggregate, cement and water for a complete batch and second lane is a TM-12 Tilt Mixer

- Dual discharge on the cement scale for holding hopper and TM-12 Tilt Mixer

- Dual discharge on the water scale for holding hopper and TM-12 Tilt Mixer

- Flop tray assembly on the batch belt to divert the aggregate to holding hopper and TM-12 Tilt Mixer

- Weighed water system with admix manifold

- Air systems pre-plumbed to all air valves

- Electrical controls to meet NEC and ULC listing

- Aggregate bin can be fed by your choice of radial stacker; fixed incline feed conveyor with turn head or individual conveyors for each bin.

- Various safety walkways available for ease of service on motors and gates

- Hagan TM-12 tilt mixer system with 14-yard capacity for true 12-yard mix at high slumps

- Pre-wired in EMT conduit to (NEC) National Electrical Code

- All batchers are NTEP certified

- All production rates theoretical

- CPMB (Concrete Manufacturers Bureau) rated and planted

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.