Silo-Top Dust Collector

Cement Dust Control

Manufactured for a cleaner environment

Uses dust cartridges & quick clamp design for ease of maintenance. Heavy-duty steel housing - no plastic or aluminum.

Key Specs

PLC Control Systems

Vince Hagan is leading the industry with technological innovations like the PLC-based (Programming Logic Controller) control systems on our equipment. This software automates the key operations of your equipment according to the manufacturer-suggested specifications, and takes the guesswork out of concrete production. Customize the programming to your specific production requirements. Once installed in a new plant you can upgrade the system without any additional hardware.

A series of flashes from an onboard light system indicates a fault code to simplify troubleshooting or production inefficiencies. Our service experts can remotely access your equipment for further diagnostics and support.

How Jet-Pulse Technology Works

The technology behind the Hagan Jet-Pulse Dust Collection System is that each row of filter bags is equipped with a solid state sequential timer that energizes a solenoid pilot valve, thus triggering the momentary pulse of compressed air through a blow pipe and down into a row of filter bags. This translates to faster and more objective means of controlling dust at your concrete plant.

As the Jet-Pulse Collection system cleans the environment, it also keeps itself clean and makes it easy for anyone to change our heavy duty, snap-in filter bags.

Our dust control system not only keeps the neighborhood clean and happy, but it also provides the option of recycling the collected dust.

- 1Dust laden air enters the collector through the bottom of the housing section.

- 2

Dust particles are collected on the outside surface of the bags

- 3

Filtered air goes to the clean air chamber and is then exhausted through the outlet

- 4

Periodic pulsing by compressed air removes the accumulated dust from the bags

- 5

Dust falls into a receptacle

- 6

Cleaning frequency and duration are adjustable by solid state timers

Specifications

| Efficiency | 99.9% At 1 Microns |

| Cloth Filtering Area | 245 FT² |

| Number of Cartridges | 7 |

| Cartridge Diameter | 8.00” O.D. |

| Cartridge Length | 36” |

| Cloth Type | Spun-Bound Polyester |

| Cloth Weight | 7.7 Oz./YD² |

| Permeability | 20 CFM/FT² @ 0.5” Water |

| Temperature Limit | 200 F° |

| Air Volume Intake | 600 CFM @ 0.5” Water |

| Exhaust Opening Size | 0.24 FT² |

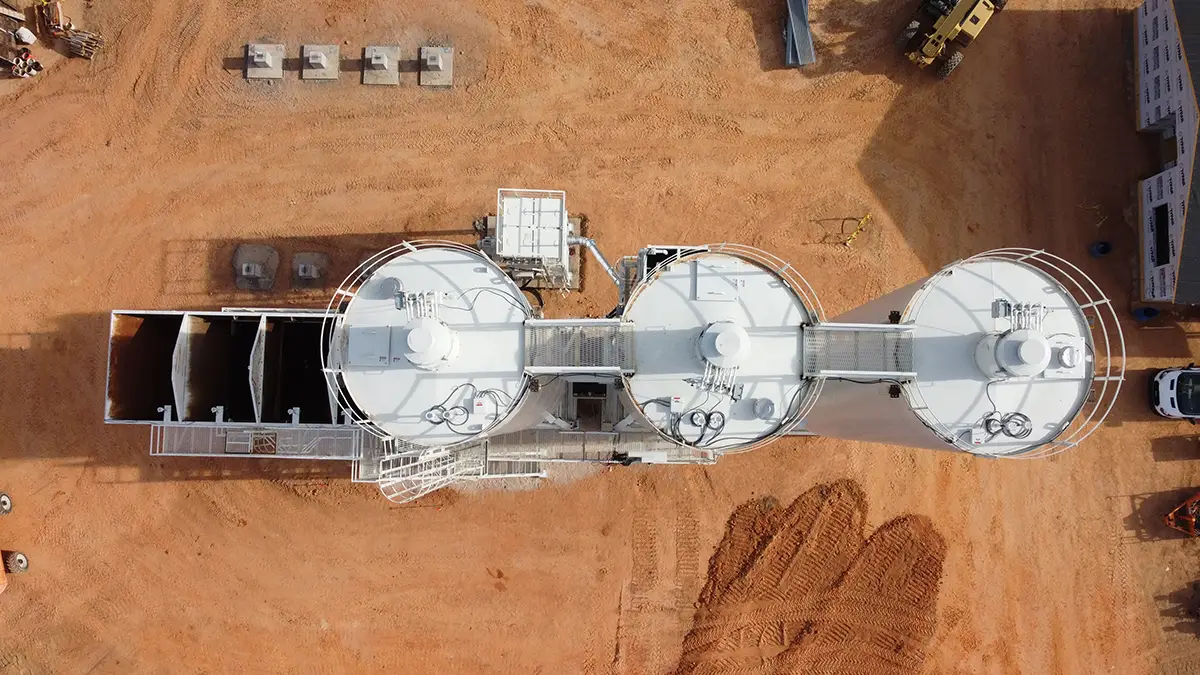

Gallery

Plants in Action

Vince Hagan recently designed, manufactured, and installed an HT Mobile Batch Plant, TM-14 Smart Tilt Mixer and HCA Silo in North Texas.

Vince Hagan recently designed, manufactured, and installed an LP Series Stationary Batch Plant, free standing dust collector, and conveyor in Texas.

Vince Hagan recently designed, manufactured, and installed an LP Series Stationary Batch Plant, free standing dust collector, and conveyor in Texas.

Vince Hagan recently designed, manufactured, and installed an LPM Series Stationary Batch Plant in Michigan.

Vince Hagan recently designed, manufactured, and installed an HT Mobile Batch Plant in central Georgia.

Vince Hagan recently designed, manufactured, and installed an LPM Series Stationary Batch Plant, free standing dust collector, and conveyor in Central South Carolina.

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.