Mobile Concrete Batching Plants

#1 Selling Mobile Plant of All Time

Since first patenting the design in 1956, The Vince Hagan company has sold over 2,000 mobile batch plants. The patented, heavy-duty steel truss design means the plant can travel as a single load of freight, including dust collection. They stand the tests of time, weather, and high production. Plus, our exclusive smart plant technology is pushing our plants to the forefront of the industry with an app that monitors sensors on vital plant components and can predict possible downtime. It also manages weekly/monthly maintenance schedules.

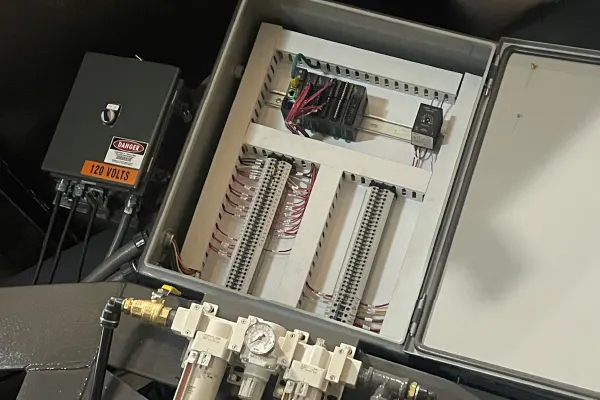

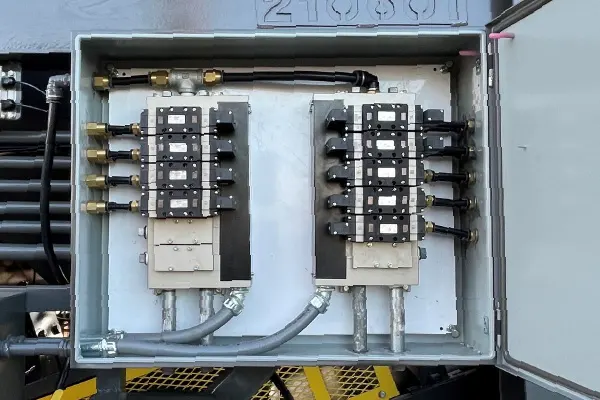

Some other standout features of our mobile series plants are: fully erected and operational in 8 hours; all components are in the truss, with the entire plant pre-wired and plumbed for air and water. After manufacturing is complete, each plant is factory tested which helps enable a trouble-free start-up and operation. Whether you want the highest production, the most aggregate storage capacity, or a plant that can grow with your business, The Vince Hagan Company is the solution for you.

Return on Investment

Vince Hagan plants are legendary for value because of proven dependability, high production, design simplicity, and longevity. When it comes to making this significant investment, you can rest assured that the center of your production relies on equipment built to last decades. Go factory direct, and cut out the middleman. We help you maximize your profits instead of paying for corporate overhead and shareholder dividends.

Expand Your Production With Mobile Batch Plant Equipment

Vince Hagan offers a number of batching equipment options for our mobile concrete batching plant to fit your company’s production and material handling requirements.

Mobile Wet Batch Production

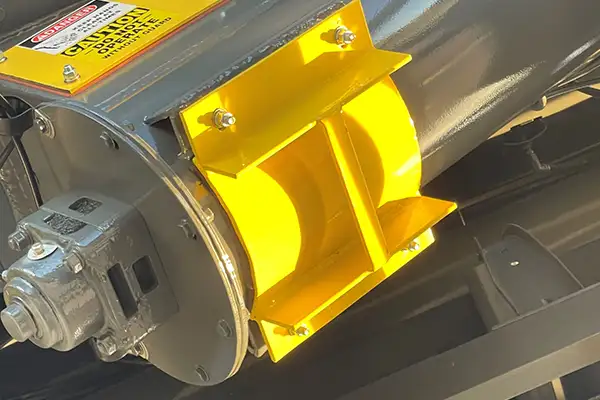

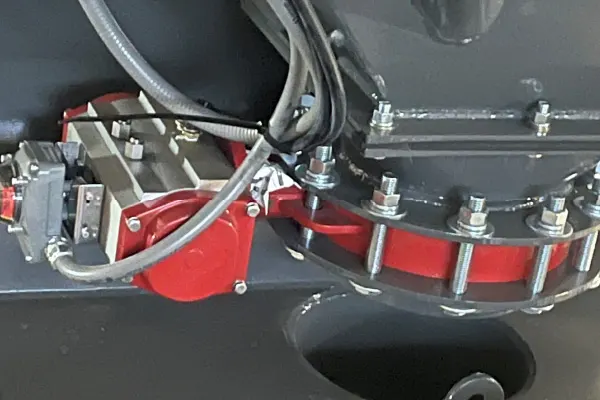

Our mobile tilt mixers are designed for a true 12-yard batch without spillage. We build mixers to last, with heavy-duty components, the largest bull ring gear in the industry, and an open design to ensure access to all moving parts for ease of maintenance.

No Need to Dig Out with 12′ 9″ Truck Clearance

No other plant and mixer combination gives you a quicker setup and dismantle time, the ability to have the fewest loads of freight, or the consistent quality produced with the compulsory mixing action of this mixer.

Twin Shaft Mixers

Our line of mobile plants pair with a variety of twin shaft mixer sizes.

HT Series Paired with Horizontal Shaft Mixer

HT Series Paired with Twin Shaft Mixer

SHT Series Paired with 12 yd³ Mobile Tilt Mixer

Hydraulic Self Erect Mobile Plants

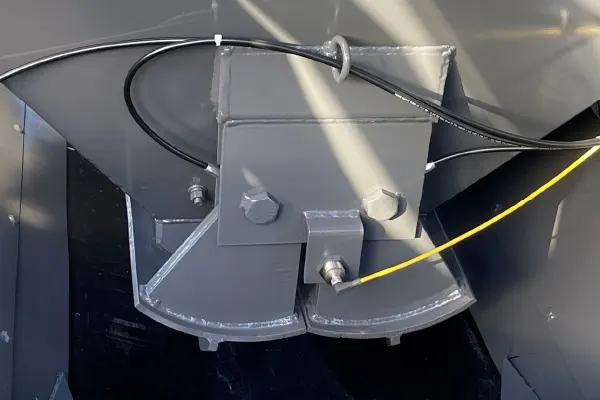

An optional upgrade, the hydraulic self erect package can be added to the mobile plant, auxiliary silo, conveyor, and horizontal shaft mixer. Our original design allows cylinders to retract, protecting them from the caustic environment.

Versatile & Innovative Mobile Batch Plant Features

One Load Transport

8 Hour Set Up

In-Truss Dust Control

Ease of Maintenance

Smart Plant

Onsite Start-Up

Nonproprietary Parts

Buy a Mobile Batching Plant From the Company that Invented It

In 1956, Mr. Vince Hagan, founder of The Vince Hagan Company, started with an original idea: he would design, build, and patent (U.S. patent #3,251,484) the very first fully mobile concrete batch plant.

Over the years, his “Haganator,” a heavy-duty truss design, became an industry icon. Today, it includes in-truss dust collection, the largest aggregate capacity, and many operator-friendly upgrades.

Vince Hagan invented the mobile batch plant in 1956 • Patented in 1966 – US3251484

Mobile Batch Plant Gallery

Mobile Batch Plants In Action

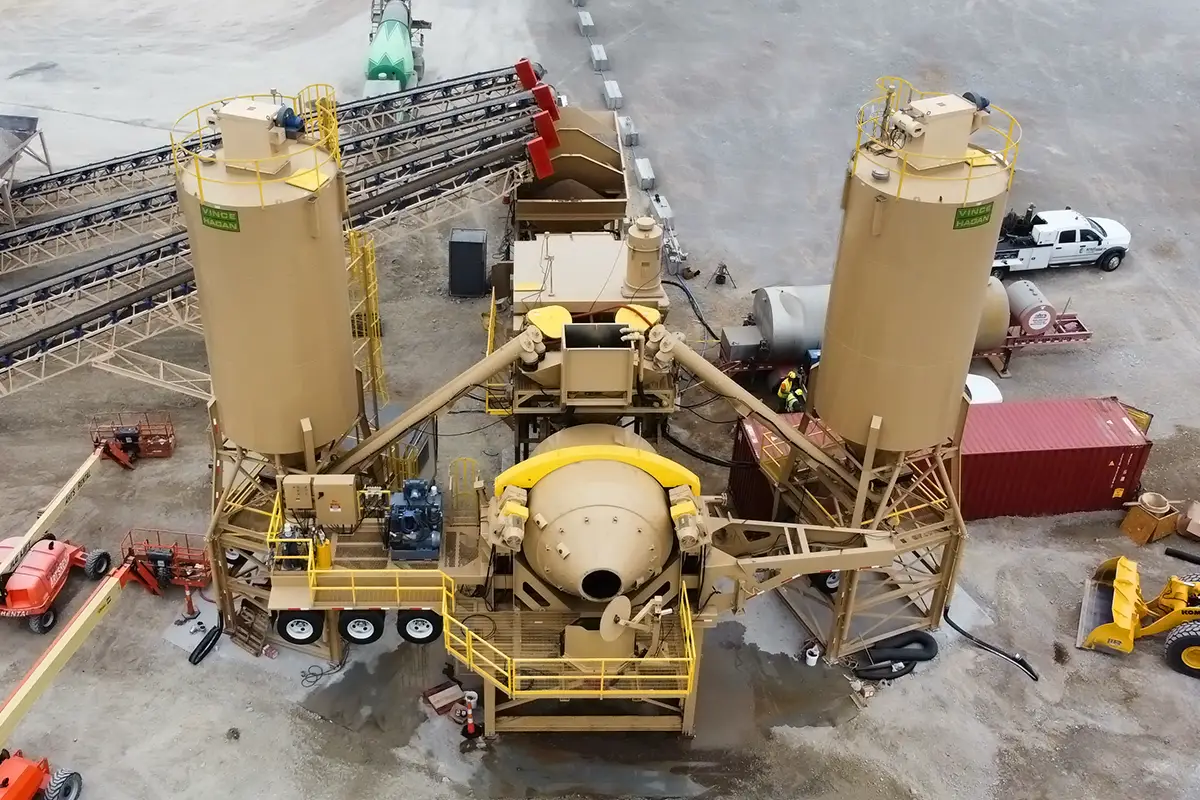

We recently manufactured an installed this SHT Series, HCA Auxiliary Silo, and Conveyors for a large volume producer in Ohio.

Vince Hagan recently designed, manufactured, and setup an HS Series batch plant to work on one of the largest infrastructure project in Mexico.

Vince Hagan recently designed, manufactured, and installed an HS Mobile Batch Plant in California.

We recently manufactured and installed this direct-charge HS Series Dry Mobile Batch Plant in the Midwest.

We custom engineered and manufactured a new Mobile Central Mix Batch Plant for Ernst Concrete in the Midwest.

Our expert service team is able to assist any producer with plant relocation and new site optimization.

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.