LP-MP Plant

Mobile Batch Plant

The Vince Hagan Company has redefined high-production paving plants.

Key Specs

Overview

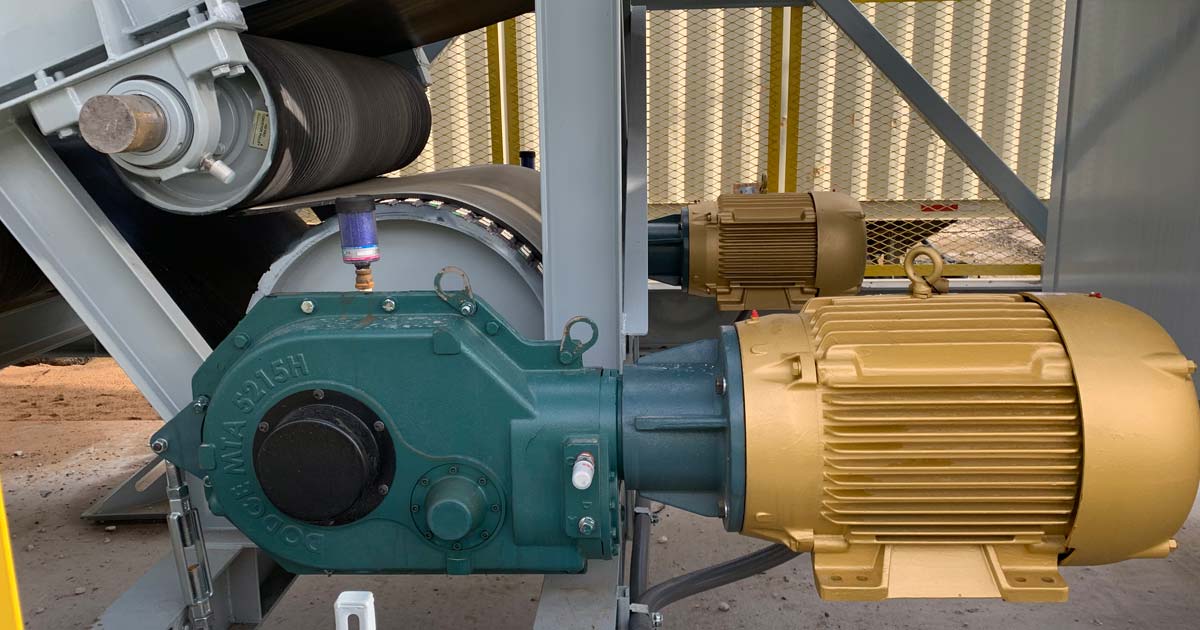

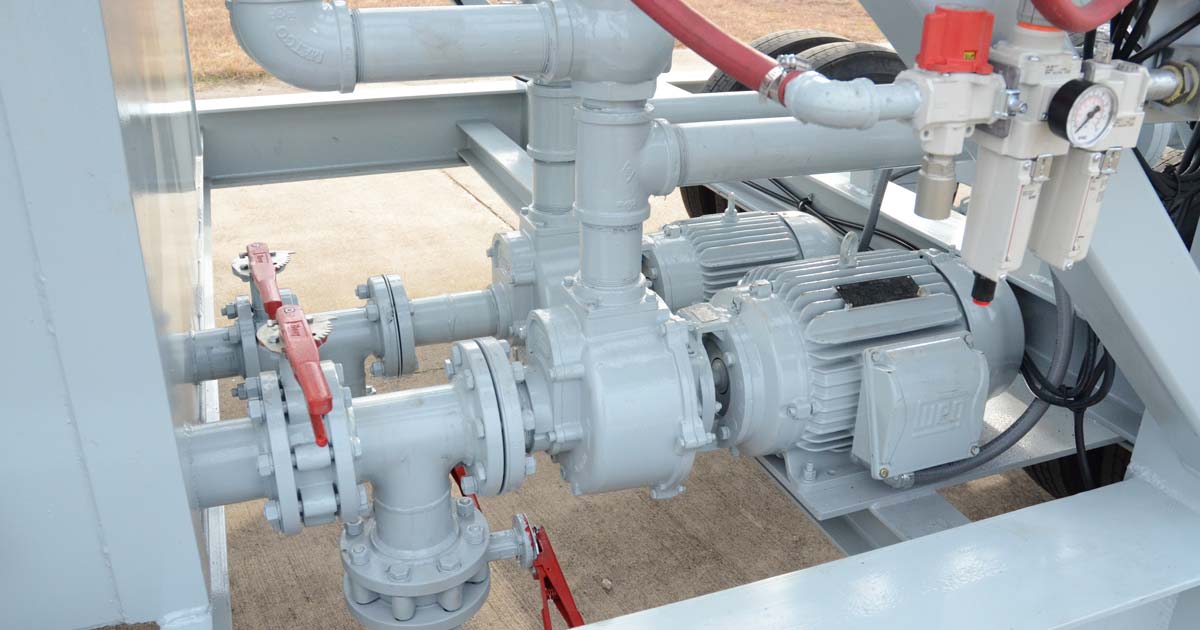

The Vince Hagan Company has redefined high-production paving plants. The Low Profile Mobile Paving Plant meets the rigorous demands of high-production projects, exceeds industry safety requirements, and delivers a production-friendly experience. The LP-MP also offers dual systems for redundancy to protect you from significant losses during large pours. When paired with the SmartVH™ Plant Monitoring System, an array of sensors which collects real-time data of plant mechanical performance, this plant alerts managers or service team members of potential issues. Benefit from exceptional mobility and an impressive four-hour erection time when you choose the company that invented the first mobile batch plant.

Features

Transport Mode

HEIGHT: 14’ 5.25” • LENGTH: 47’ 1” • WEIGHT: 72,000 lbs

HEIGHT: 13’ 4” • LENGTH: 68’ 3” • WEIGHT: 66,000 lbs

HEIGHT: 14’ 5” • LENGTH: 60’ 5.75” • WEIGHT: 70,000 lbs

Gallery

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.