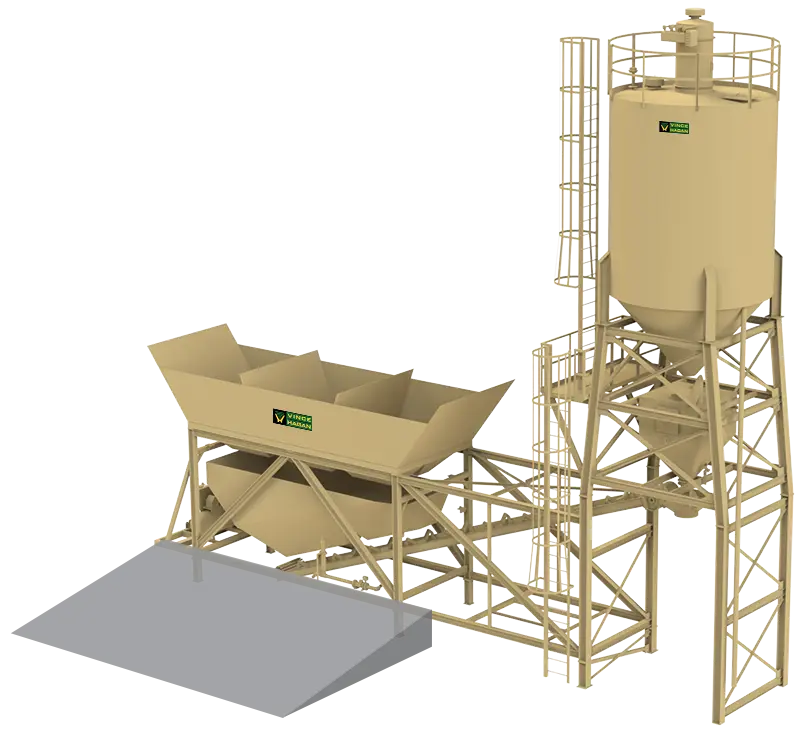

LP Series

Stationary Batch Plant

The LP (Low Profile) Series is one of our most popular plants that meets the demands of a wide range of markets.

Key Specs

Overview

The LP (Low Profile) Series is one of our most popular plants for producers across the nation. This plant meets the demands of a wide range of markets, and has all of the features that go into a large stationary batch plant while easily traveling in two loads. The cement silo and cement batcher move together as one load, and the aggregate section with transfer belt moves as the other. This is the perfect plant for startup producers or those looking to expand into new regions.

Direct Charge Option

Allows a front-end loader to charge aggregate in bins

Features

Add-Ons

Gallery

Plants in Action

We recently manufactured and installed a direct charge LP Series Stationary Concrete Batching Plant in Canada.

We recently manufactured and installed a LP Series Stationary Concrete Batching Plant in South Carolina.

The Vince Hagan Service Team recently installed a newly manufactured LP Series Dry Batch Plant, Radial Stacker, and Dust Collection system for ready mix production in Texas.

We recently custom manufactured and installed LP Series Dry Stationary Concrete Batching Plant for a Texcrete Ready Mix production facility in the South.

Vince Hagan recently custom manufactured and installed an LP Series Dry Stationary Concrete Batching Plant in Oklahoma.

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.