HSM Series

stationary Batch Plant

The HSM series brings together mobility and high production capabilities.

Key Specs

Overview

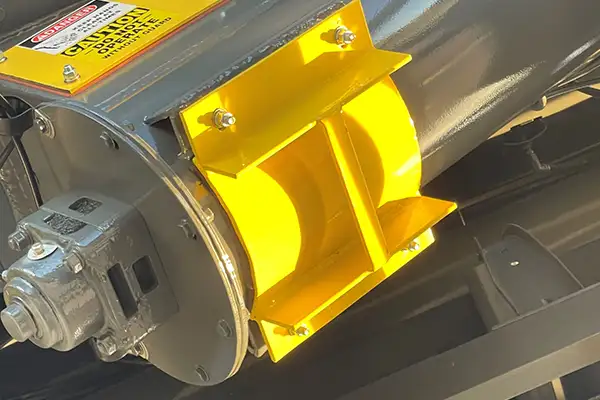

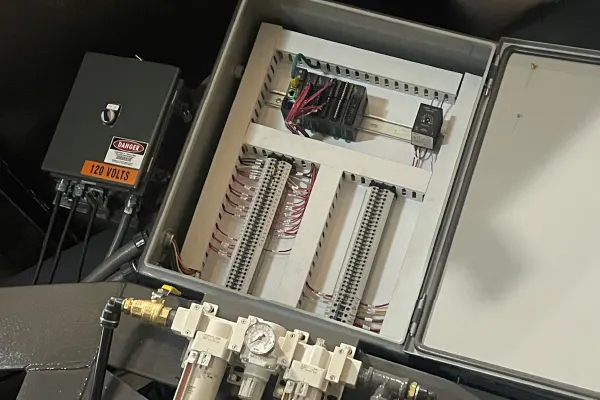

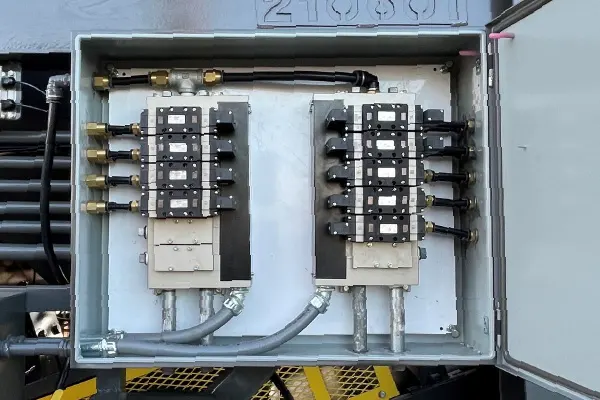

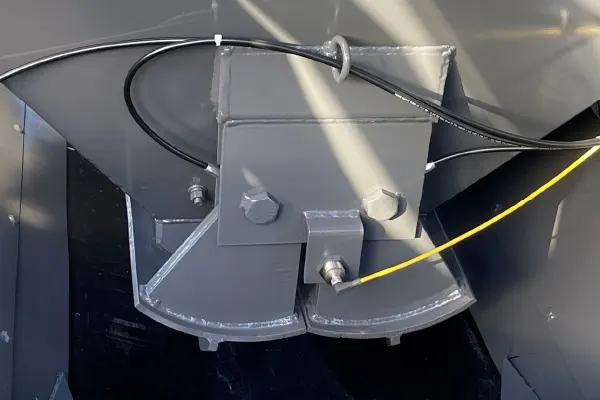

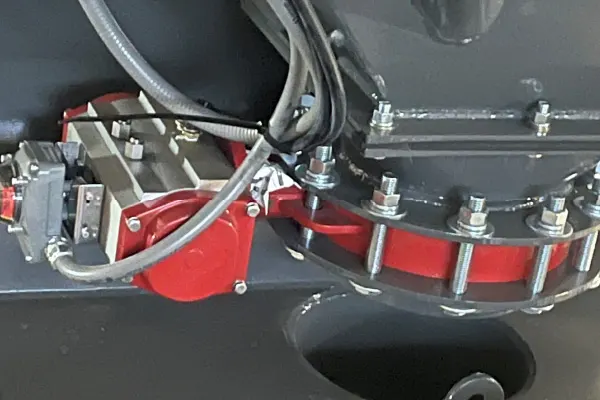

The HSM Series batch plant brings together the mobility of the HT Series mobile plant with the profile of an LP Series stationary plant. Pairing an in-truss cement silo and an overhead silo allows for robust cementitious storage while maintaining a low profile. The Hagan patented heavy-duty steel truss design incorporates all wiring, piping, air systems, and walkways so everything can easily travel and quickly erect at a new location.

Features

Add-Ons

Gallery

Plants in Action

Vince Hagan recently custom designed, manufactured, and installed an HSM Stationary Batching Plant for Canton Concrete in Mississippi.

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.