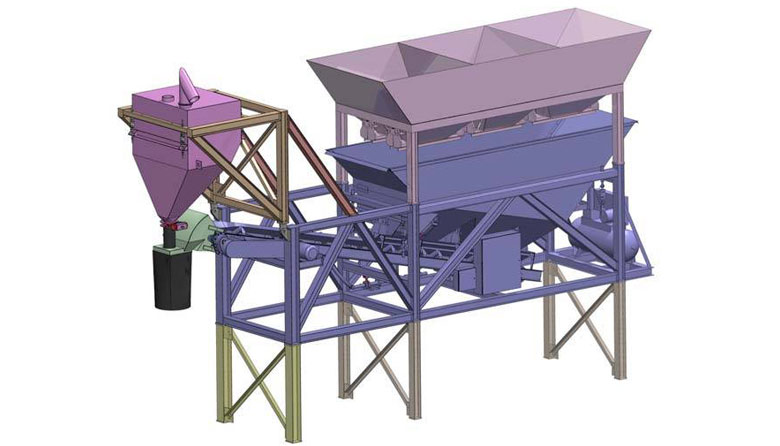

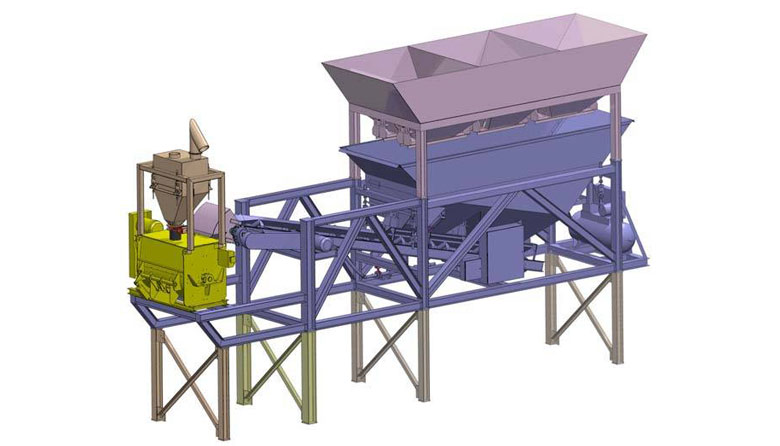

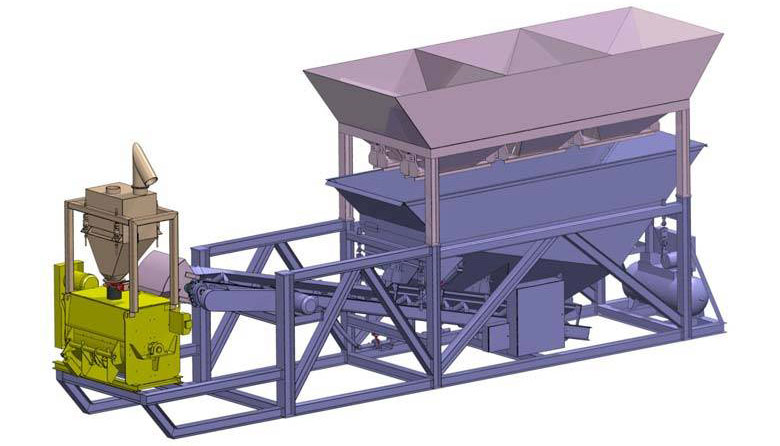

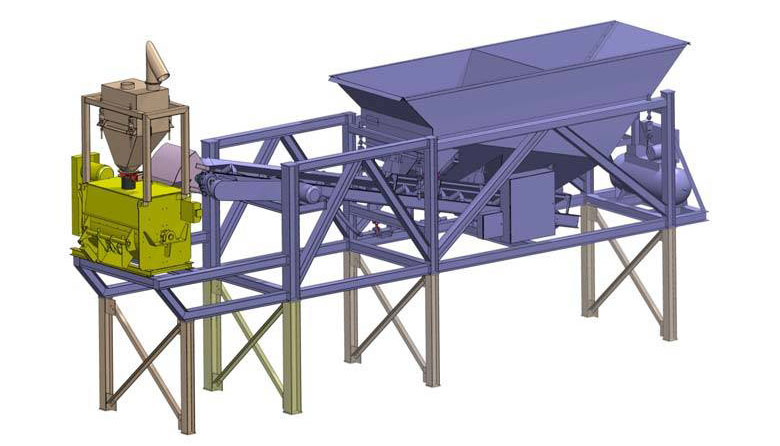

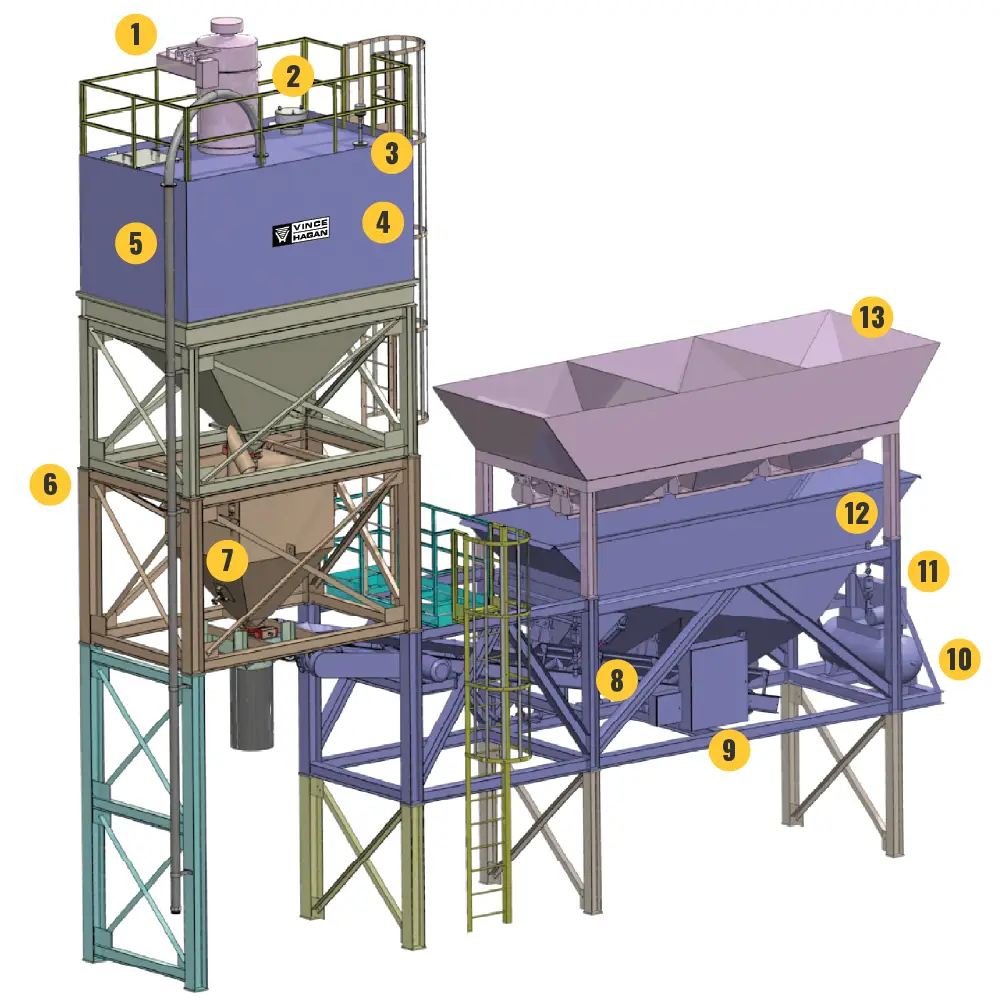

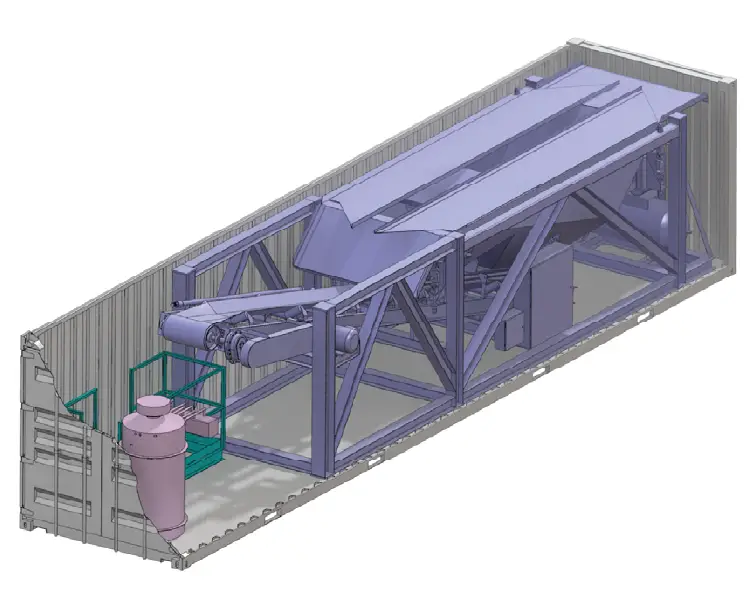

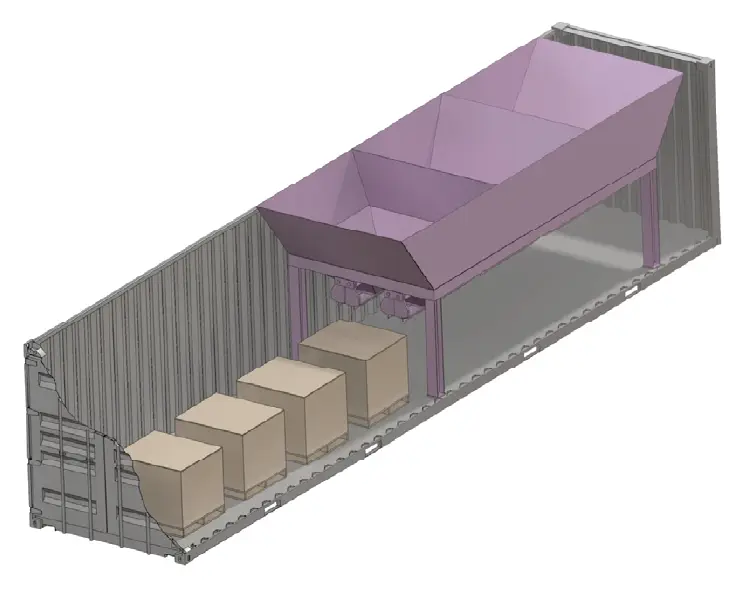

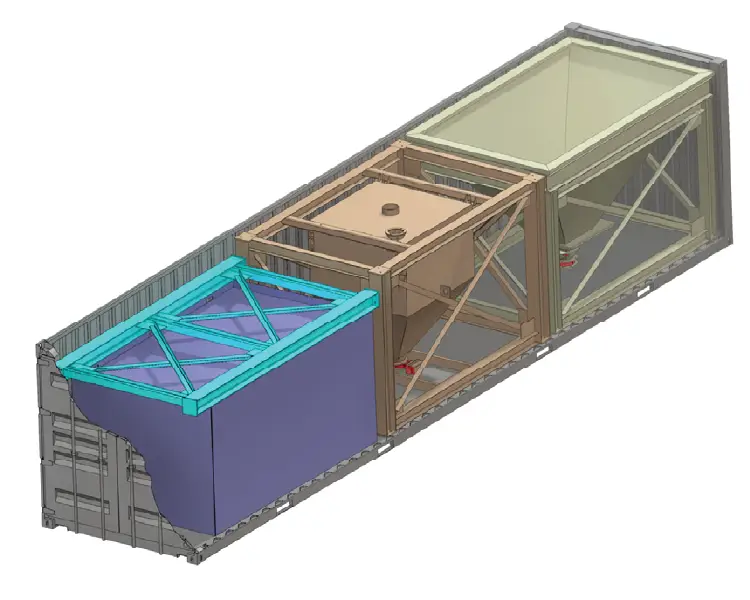

Containerized Plant

Stationary Batch Plant

The LPC stationary modular concrete batch plant provides for custom design along with lower shipping costs. This plant fits conveniently inside shipping containers. With a large selection of plants ranging from decumulative to accumulative and dry to wet batch, the LPC plant provides the options that will meet your batch plant needs. Use the LPC plant in locations where you require layout flexibility.

Features

- 1

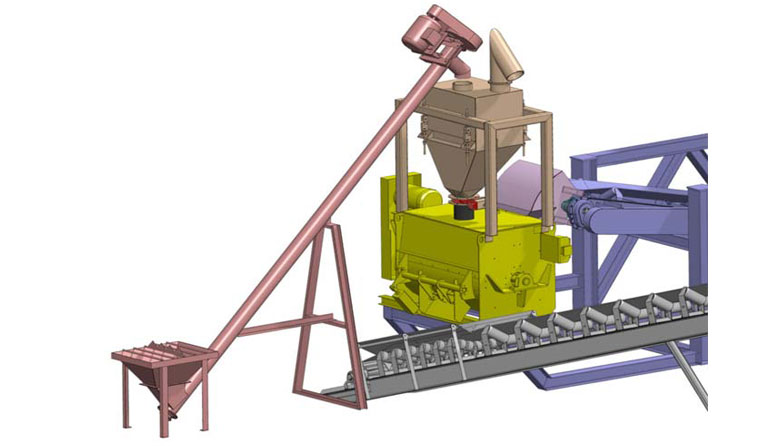

Silo-Top Dust Collector

- 2

Pressure Relief Valve

- 3

High Level Indicator

- 4

200 - 500 BBL (34.1 - 85.2 metric ton) Overhead Cement Silo

- 5

Fill Pipe

- 6

4 Point Cement Load Cell System

- 7

6 or 12 YD³ Cement Batcher (4.58 or 9.17 M³)

- 8

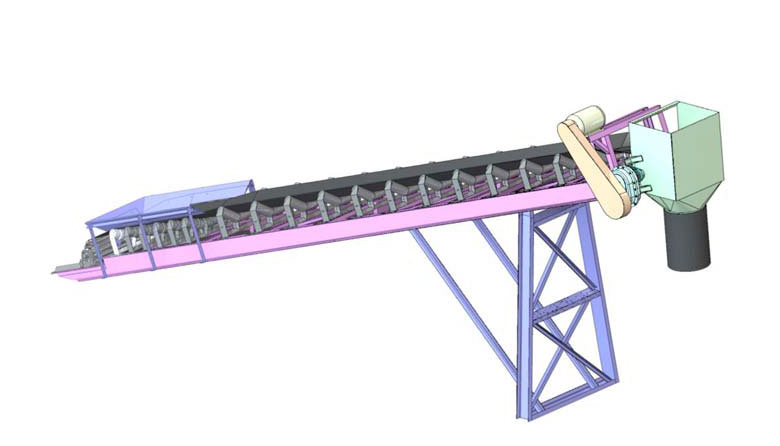

24”, 30”, & 36” batch transfer belt (610 mm, 762 mm, 914 mm)

- 9

Electrical Panel

- 10

10 HP Air Compressor With 120 Gallon Tank

- 11

4 Point Aggregate Load Cell System

- 12

6 or 12 YD³ Aggregate Batcher (4.58 or 9.17 M³)

- 13

40 Ton Aggregate Bin (36.2 Metric Ton)

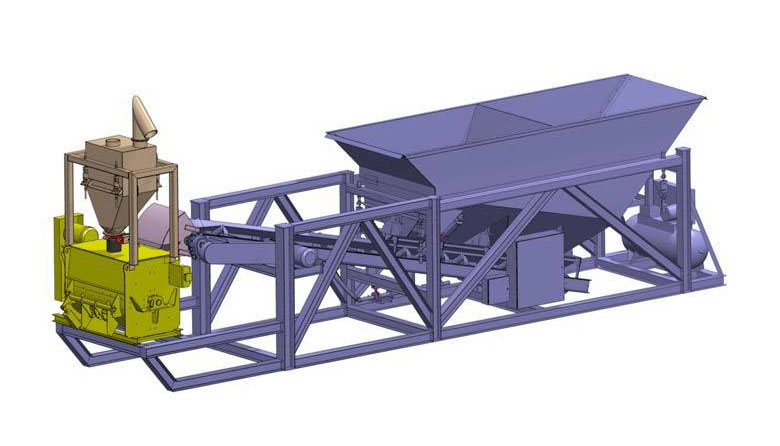

Optional Equipment

Auxiliary Silo

Cement Sack Feeder

Wet Belt Conveyor

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.