Stationary Concrete Batching Plants

Design-Manufactured Total Solution

Vince Hagan stationary batch plants set the industry standard for reliability and longevity. Our plants address your needs for robust storage, a uniform mix, and the high-production demands of both large and small projects. We will custom design your plant to meet your site layout needs while considering seismic and high-wind requirements for your location. Plus, our exclusive smart plant technology is pushing our plants to the forefront of the industry with an app that monitors sensors on vital plant components and can predict possible downtime. It also manages weekly/monthly maintenance schedules.

Trusted Install by Manufacturer

Installation of your equipment is just as critical as the purchase. And with over 60 years of turnkey installation services, Vince Hagan is your trusted industry partner. All installations include comprehensive operational and maintenance training to assure your equipment is running safely and efficiently.

Return on Investment

Vince Hagan plants are legendary for value because of their proven dependability, high production, and longevity. When it comes to making this significant investment, you can rest assured that the center of your production relies on equipment built to last for a generation. Go factory direct, and cut out the middleman. We help you maximize your profits instead of paying for corporate overhead and shareholder dividends.

Expand Your Production With Stationary Batch Plant Equipment

Vince Hagan offers a number of batching equipment options for our stationary concrete batching plant to fit your company’s production and material handling requirements.

Stationary Wet Batch Production

We designed our stationary tilt mixers for a true 12-yard batch without spillage. Your mixer includes heavy-duty components, the largest bull ring gear in the industry, and an open design to ensure access to all moving parts for ease of maintenance.

Twin Shaft Mixers

Our line of stationary plants pairs with a wide variety of twin shaft mixer sizes.

LPM Series Paired with Twin Shaft Mixer

LPM Series Paired with Tilt Mixer

Dual Alley LPM Paired with 12 YD³ Stationary Tilt Mixer

Stationary Batch Plant Gallery

Stationary Batch Plant Features

Stationary Batch Plants In Action

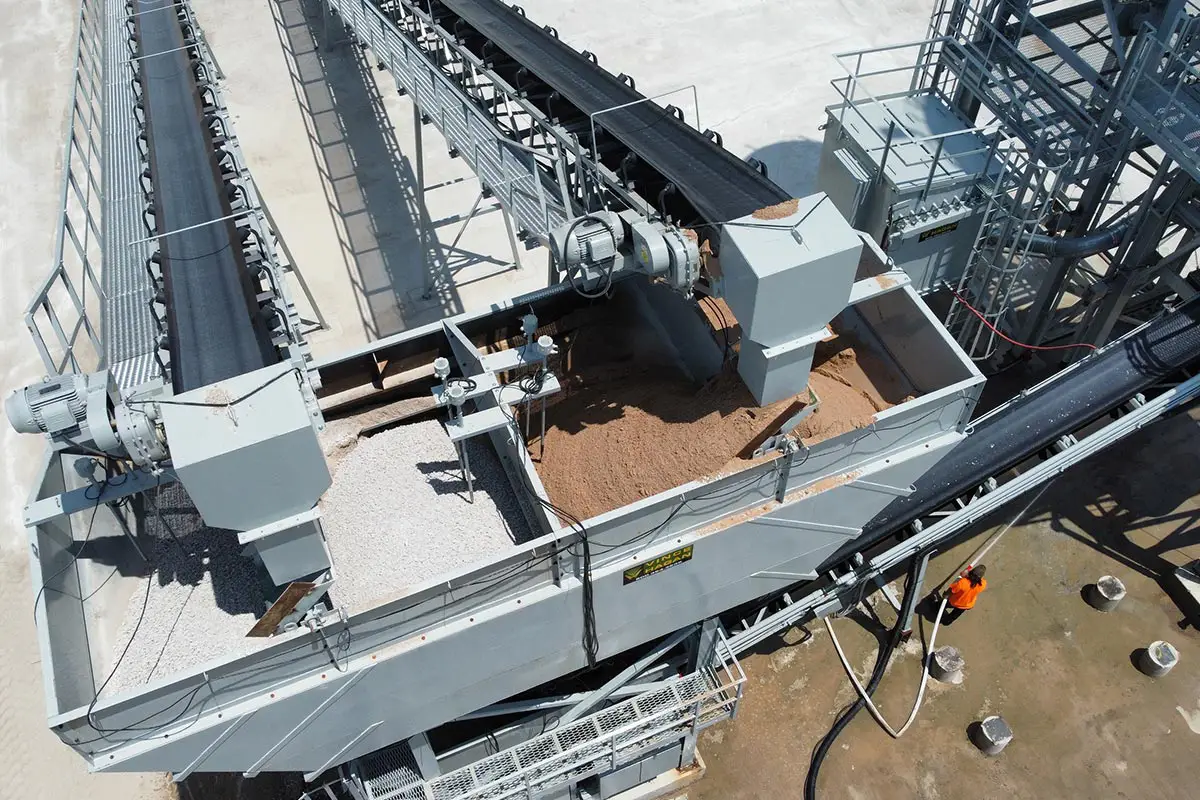

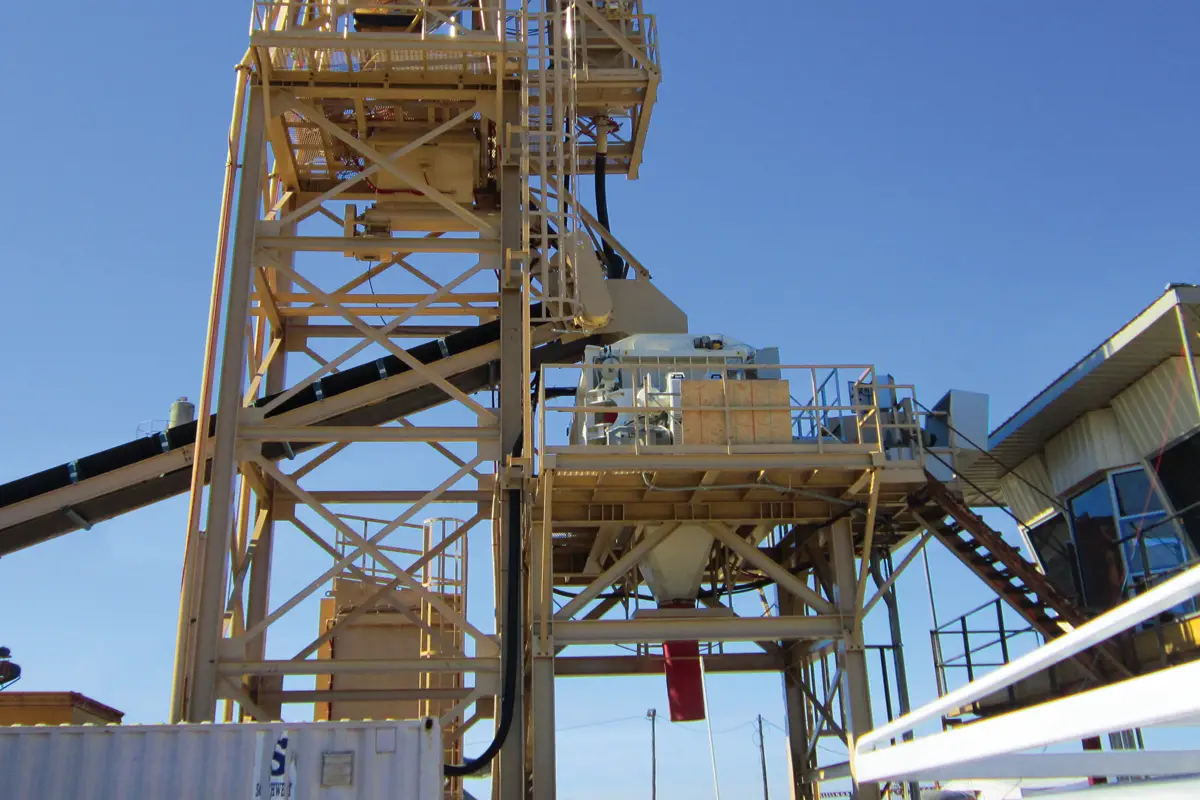

We recently manufactured and installed a direct charge LP Series Stationary Concrete Batching Plant in Canada.

We recently manufactured and installed a LP Series Stationary Concrete Batching Plant in South Carolina.

We recently custom designed and installed this high-production with robust storage LPM Series plant in the Carolinas.

The Vince Hagan Service Team recently installed a newly manufactured LP Series Dry Batch Plant, Radial Stacker, and Dust Collection system for ready mix production in Texas.

We recently custom manufactured and installed LP Series Dry Stationary Concrete Batching Plant for a Texcrete Ready Mix production facility in the South.

Getting big production out of a small footprint. Vince Hagan innovated, manufactured, and installed a Dual Alley LPM Stationary Concrete Batching Plant with a TM-12 Smart Tilt Mixer for Tec-Crete Transit Mix Corporation in the heart of New York City.

Request a Quote

Since 1956, Vince Hagan has been the standard for batching plants and industry innovation. Fill out the form below to get a quote started with the most trusted name in the industry.